-

nanhai,foshan, CN 526200

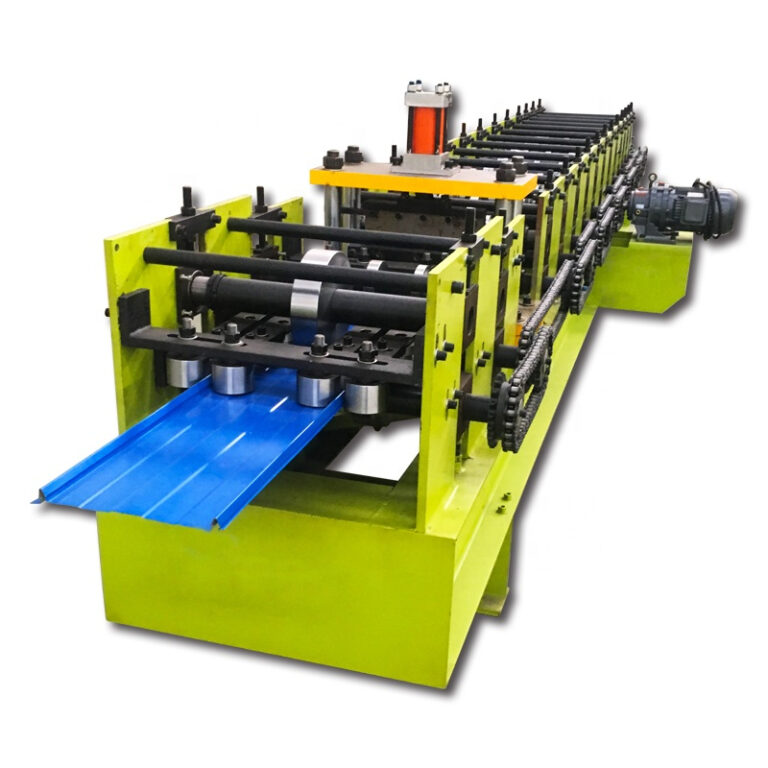

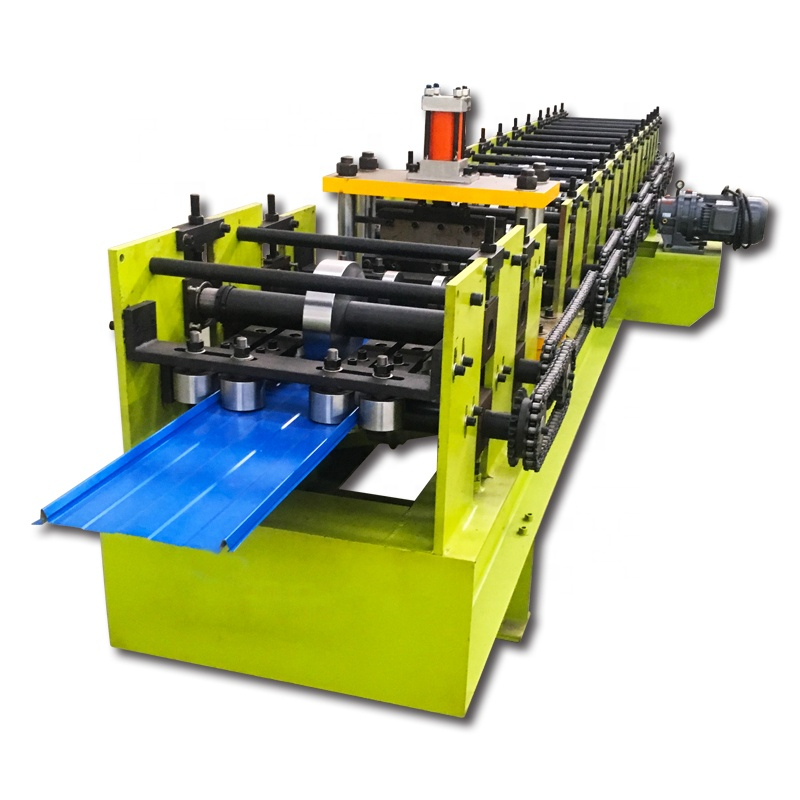

Metal Siding Roll Forming Machine

Trust Our Roll Forming Machine Solutions for Your Metal Rollforming Needs

As a premier manufacturer of roll forming machines, we offer comprehensive solutions tailored to ventilation duct manufacturers, door and gate manufacturers, and ventilation duct engineering contractors. Our advanced equipment is built for superior precision, productivity, and automation, empowering you to produce high-quality metal products while optimizing your production processes. When you choose us, you gain a partner dedicated to your success, providing not only cutting-edge machinery but also unparalleled expertise and dedicated support. We’re confident that you will be satisfied with our products.

Product Outline

H2: Enhance Productivity with Advanced Roll Forming Equipment

H2: Achieve Unmatched Precision with Our Roll Forming Systems

H2: Integrate Automation for Seamless Metal Panel Production in 2024

Product Description

H2: Enhance Productivity with Advanced Roll Forming Equipment

In the fast-paced metal rollforming industry, maximizing productivity is key to staying ahead of the competition. Our advanced roll forming machines are designed to meet your specific needs, providing a significant boost to your manufacturing capabilities. These machines are engineered for speed and efficiency, allowing you to produce metal panels, trim, and other components at a faster rate than ever before. If your business is metal roofing, we can provide equipment that meets your specific needs.

Our equipment is built with high-quality components and incorporates the latest technological advancements. This ensures not only high-speed operation but also long-term reliability, minimizing downtime and maximizing your return on investment. With our roll forming machines, you can meet tight deadlines, increase output, and ultimately enhance your bottom line. Our machines can also be customized to meet the specific needs of each client. This ensures that your equipment can meet the demands of your business and your customers.

Technical Specifications

| Feature | Specification |

|---|---|

| Material | Galvanized Steel, PPGI, Aluminum |

| Material Thickness | 0.3 – 1.2 mm (Customizable) |

| Material Width | Up to 1500 mm (Customizable) |

| Forming Speed | Up to 30 m/min (Customizable) |

| Forming Stations | 10 – 30 (Customizable) |

| Drive System | Servo Motor with Planetary Gearbox |

| Control System | PLC with Touchscreen Interface |

| Safety Features | Emergency Stop, Safety Interlocks |

| Warranty | 1 Year |

H2: Achieve Unmatched Precision with Our Roll Forming Systems

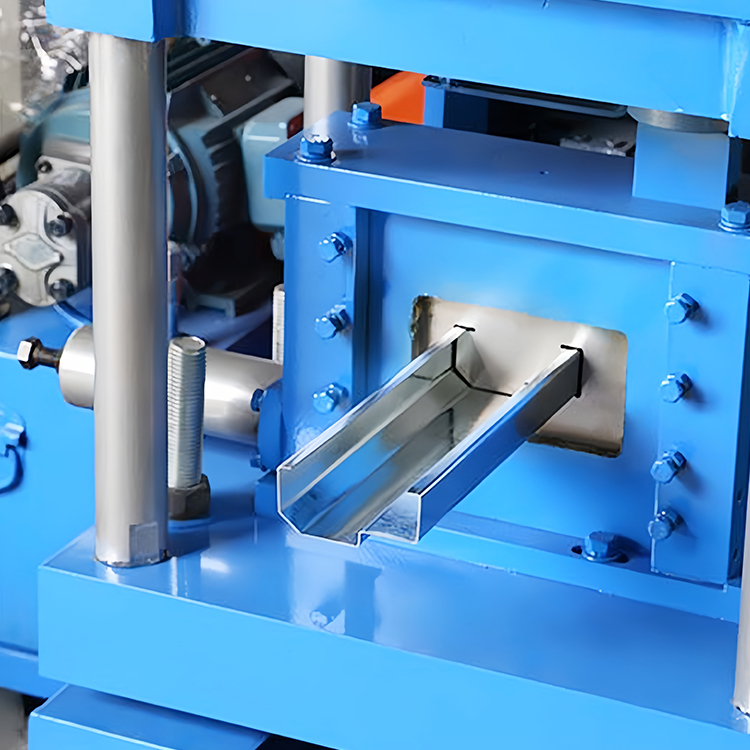

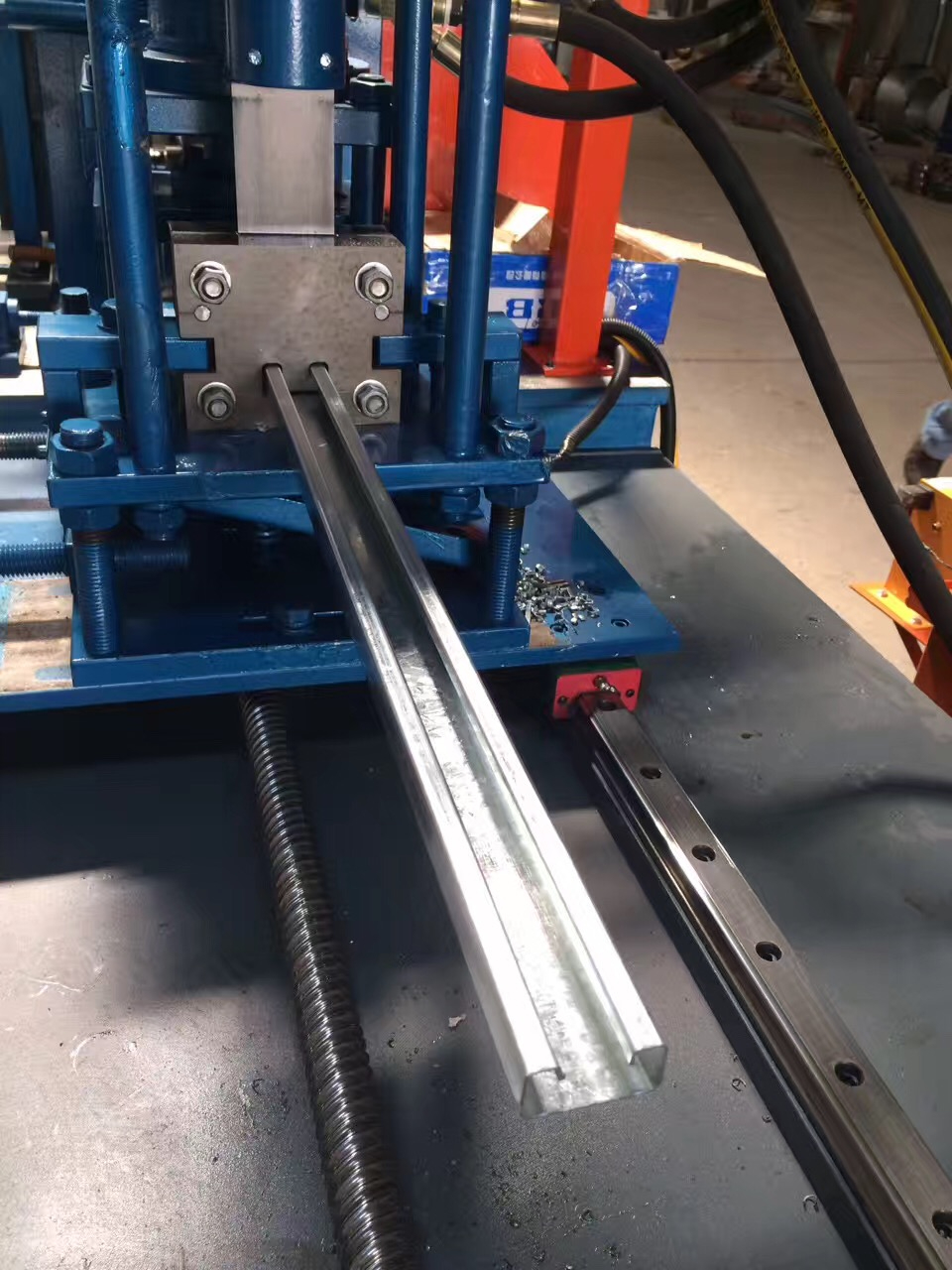

Precision is the hallmark of quality in metal fabrication. Our roll forming systems are engineered to deliver exceptional accuracy, ensuring that every sheet metal component you produce meets the most exacting standards. Each machine features precisely designed rollers that gradually shape the metal coil into the desired profile, guaranteeing consistent dimensions and a flawless finished product.

This commitment to precision extends to every aspect of our machinery, from the rigid frame construction to the advanced control systems. By minimizing deviations and ensuring uniformity, our roll forming machines help you reduce material waste, eliminate costly rework, and deliver superior products that enhance your reputation for quality. If you need equipment to make a seamless gutter, we can develop a machine for you. When you choose our roll forming systems, you’re investing in accuracy that translates into tangible benefits for your business.

“Their roll forming machines have significantly improved the quality of our products. The precision is remarkable.” – A satisfied customer in the door and gate manufacturing industry.

Usage Instructions:

- Load the metal coil onto the uncoiler.

- Feed the sheet metal through the entry guide into the roll former.

- Set the desired profile and production parameters on the machine’s control panel.

- Start the machine and monitor the forming process.

- The finished roll forming products will be automatically cut to the specified length.

H2: Integrate Automation for Seamless Metal Panel Production in 2024

Automation is transforming the metal fabrication industry, and our roll forming machines are at the forefront of this revolution. Designed for seamless integration into your panel lines, our equipment can automate your production process, significantly increasing output and reducing labor costs. This is also important for the production of wall panel products. With features like automatic coil feeding, in-line punching, and cut-to-length systems, our machines streamline your workflow and minimize manual intervention. Our machines will help equip you for success.

By embracing automation, you not only boost productivity but also enhance consistency and quality. Our roll forming systems are equipped with advanced control systems that ensure precise and repeatable results, every time. In 2024, staying competitive means embracing the power of automation, and our machines are designed to help you do just that. We also offer a full line of metal building component machines. Our machines can help you maximize your output.

Environmental Impact:

- Our roll forming machines are designed to minimize energy consumption.

- The rollforming process generates minimal scrap compared to other metal forming methods.

- Our machines are compatible with recycled sheet metal, promoting sustainability.

Customer Reviews

| Customer | Review |

|---|---|

| Ventilation Solutions Inc. | “The automation features of their roll forming machine have significantly increased our productivity and reduced labor costs.” |

| Secure Gate Manufacturing | “We’re impressed with the precision and reliability of the machine. It has become an essential part of our production line.” |

| HVAC Engineering Contractors | “The seamless integration into our existing panel lines has been a game-changer. We’re producing high-quality panels faster than ever before.” |

With our machines, you will be able to produce a wide range of products. Contact us today to learn more about how our roll forming machines can benefit your business. Our sales team is ready to answer your questions and provide you with a custom quote. If you need a special tool, we can create it. We have the expertise to meet all of your needs, and we are happy to provide delivery and installation. Our dedicated customer service team is ready to assist you.

Final Output: Product Advantage Summary

“Boost your productivity and precision with our automated roll forming machines! Tailored for your industry, they deliver top-quality metal products with unmatched efficiency.”

Help Center

Have a query? Please check this question and answers

A: Roll Forming Offers Superior Speed, Consistent Quality, Minimal Waste, And Lower Labor Costs For High-Volume Standardized Profiles.

To a certain extent, yes. Modern door frame roll forming machines offer a degree of flexibility. Adjustments can be made to accommodate different profile widths and gauges. However, significant variations in profile shape usually require different sets of tooling (rollers). We can discuss your specific product range, and I can advise you on the machine configuration and tooling options that would best suit your needs, whether it’s a machine with quick-change tooling capabilities or potentially multiple machines for vastly different product lines.

After the subscription license expires, HappyAddons Pro will stop working. Without the license key, you couldn’t use the pro features and widgets of HappyAddons. So you need to renew your license before it expires. That’s the way to prevent the site breaking issue.

And don’t worry, we will send you a reminder through email and admin notice banner of your WordPress dashboard.

You will just need to have the latest version of Elementor installed on your website to be able to use the HappyAddons.

You will just need to have the latest version of Elementor installed on your website to be able to use the HappyAddons.

After the subscription license expires, HappyAddons Pro will stop working. Without the license key, you couldn’t use the pro features and widgets of HappyAddons. So you need to renew your license before it expires. That’s the way to prevent the site breaking issue.

And don’t worry, we will send you a reminder through email and admin notice banner of your WordPress dashboard.

HappyAddons is a unique collection of Addons to power up the Elementor Page Builder plugin. It works with the WordPress and Elementor Page Builder to customize your WordPress blog or Business sites.