-

nanhai,foshan, CN 526200

Top 3 Roll Forming Machine Manufactor

Started From 1995 Year.

With advanced cold roll forming technology and craftsmanship, we create industry-leading machinery that helps clients enhance production efficiency and product quality, ensuring every innovation meets the highest standards.

01.

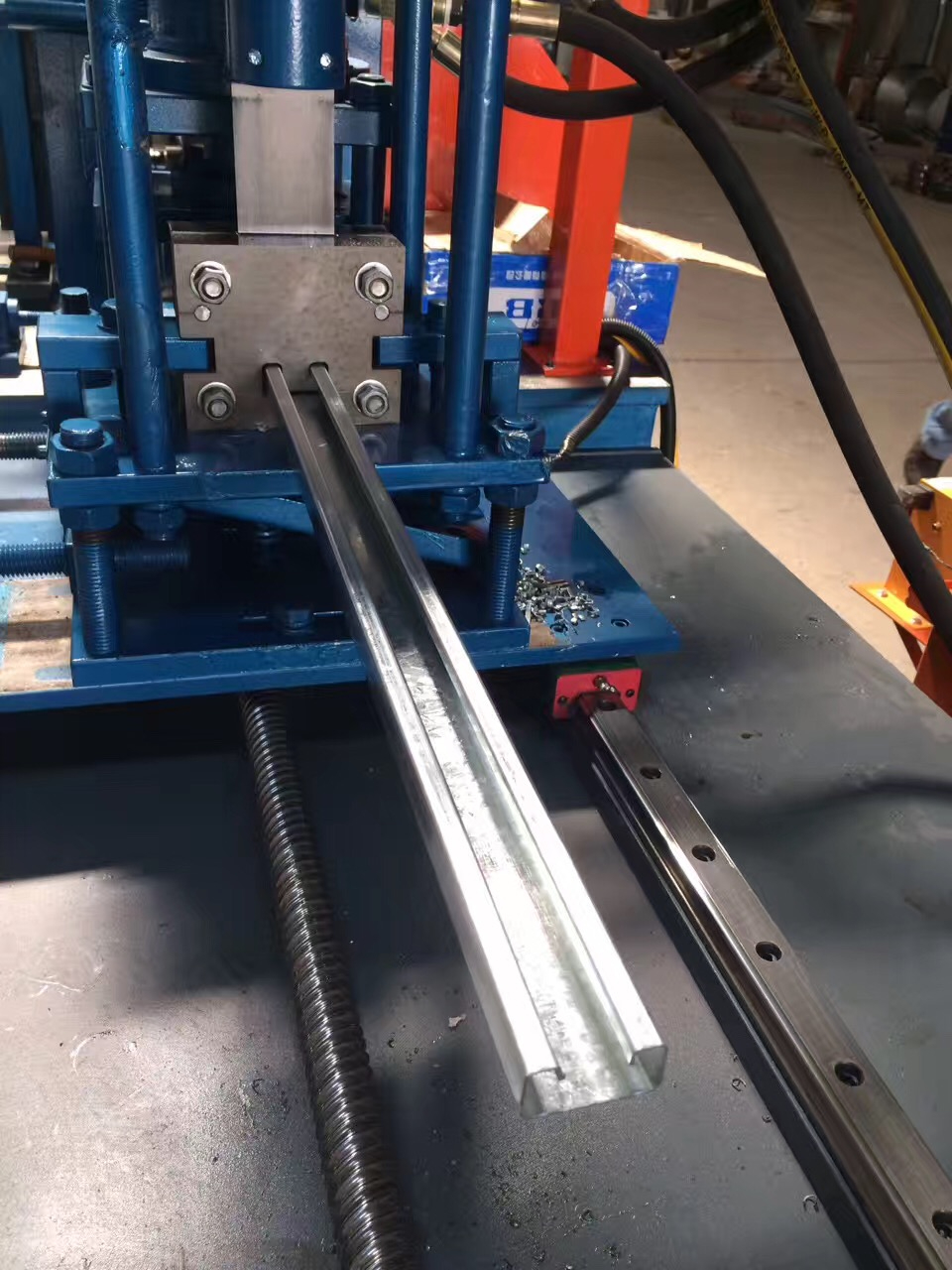

Unmatched Speed and Productivity

Our roll forming machines boost output 4-18 times. Portable machine fabricates sheet metal faster. The roll former can process any sheet in the market.

02.

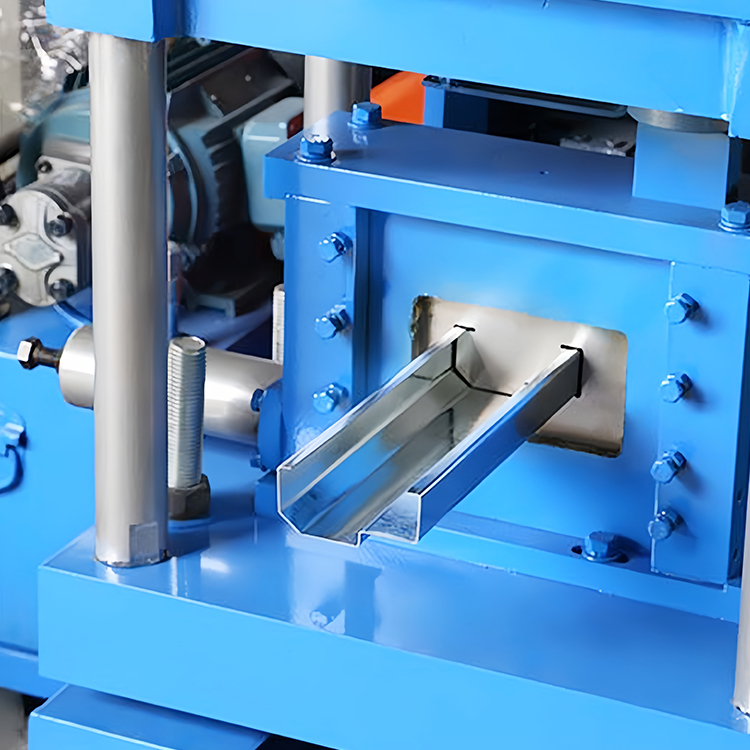

Exceptional Accuracy and Consistency

Roll forming with our machine creates precise, uniform metal components. Every sheet is in the correct gauge.

03.

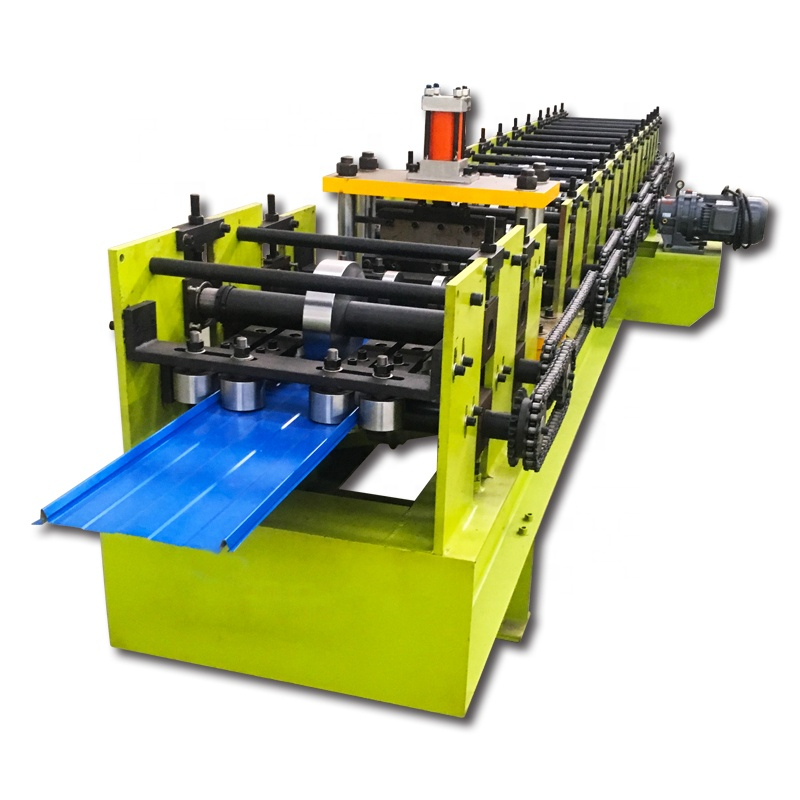

Tailored Solutions and Cost Savings

Custom roll forming solutions. Our roll former is tailored to your needs and saves money. Our machine can also do metal rollforming.

Why Choose Us

For over two decades, we have been a leading manufacturer of high-quality roll forming machinery, serving a diverse range of industries, including ventilation duct fabrication. We specialize in creating innovative, robust, and easy-to-use machines and systems that empower our clients to achieve maximum productivity and efficiency. We are not just a supplier; we also sell Tennsmith and NTM, and we’re a partner committed to your success. Our roll forming products are well known in the industry.

Unmatched Speed and Productivity

Exceptional Accuracy and Consistency

Tailored Solutions and Cost Savings

Products We Are Proud Of

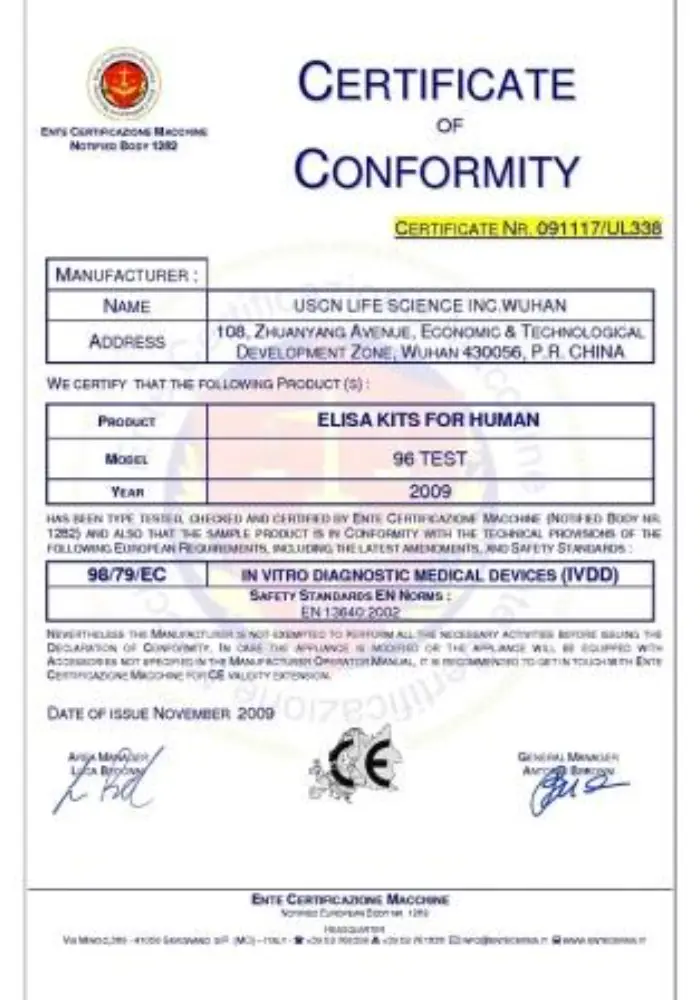

Certificates Obtained

What Our Client’s Say

Frequently Asked Questions

A: Absolutely! We can tailor our rollformer and machines to your exact specifications, including custom profile designs and machine configurations.

A: Turnaround times can vary. Please contact us to get a quote and discuss your specific requirements.

Latest from Blog

The Ultimate Guide to Roll Form Design: Best Practices and Tooling Insights

Understanding Roll Forming Machines