-

nanhai,foshan, CN 526200

Fully Automatic Box Beam Roll Forming Machine

🕢 [ Fill out the form and we will respond within 30 minutes! ]

Revolutionize Your Production with Our Advanced Box Beam Roll Forming Machine for Rack Systems – Contact Us for a Detailed Specification and Installation Guide

As a leading roll forming machine manufacturing plant, we specialize in providing high-quality, efficient machinery solutions for various industries. Our box beam roll forming machine is specifically designed to meet the demanding needs of ventilation duct manufacturers, door and gate manufacturers, and ventilation duct engineering contractors. This machine is an essential tool for producing durable and precise box beams used in various racking systems. Our box beam roll forming machine enhances production efficiency, reduces labor costs, and ensures consistent product quality. By investing in our state-of-the-art machinery, you can significantly improve your manufacturing capabilities and meet the growing market demands. Our commitment to excellence and customer satisfaction sets us apart. We offer comprehensive support, from detailed specifications to on-site installation and commissioning, ensuring you get the most out of your investment. Don’t hesitate to contact us to learn how our box beam roll forming machine can transform your production process.

Advanced Hydraulic Decoiler and Precision Roll Forming for Box Beam Production

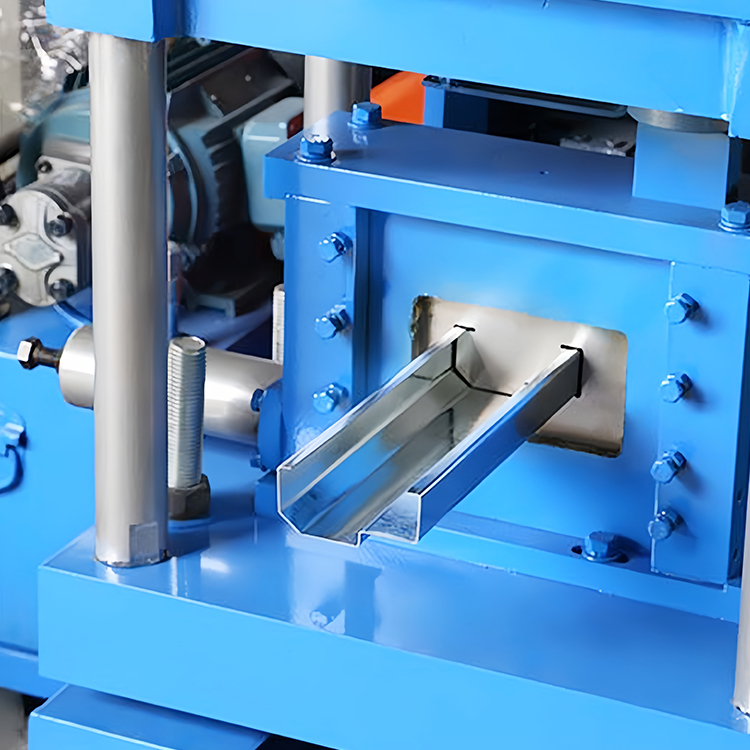

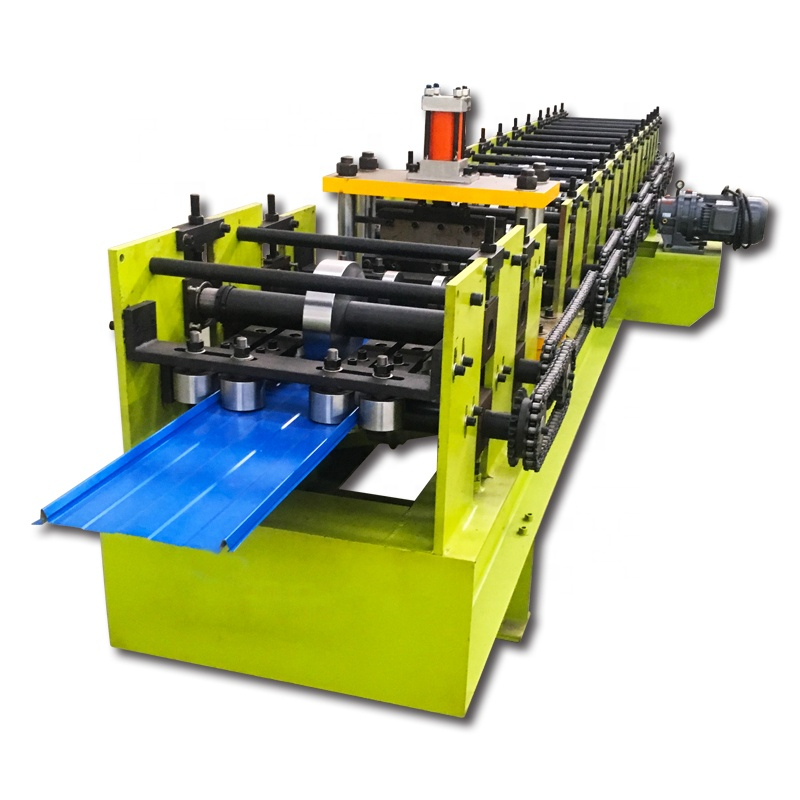

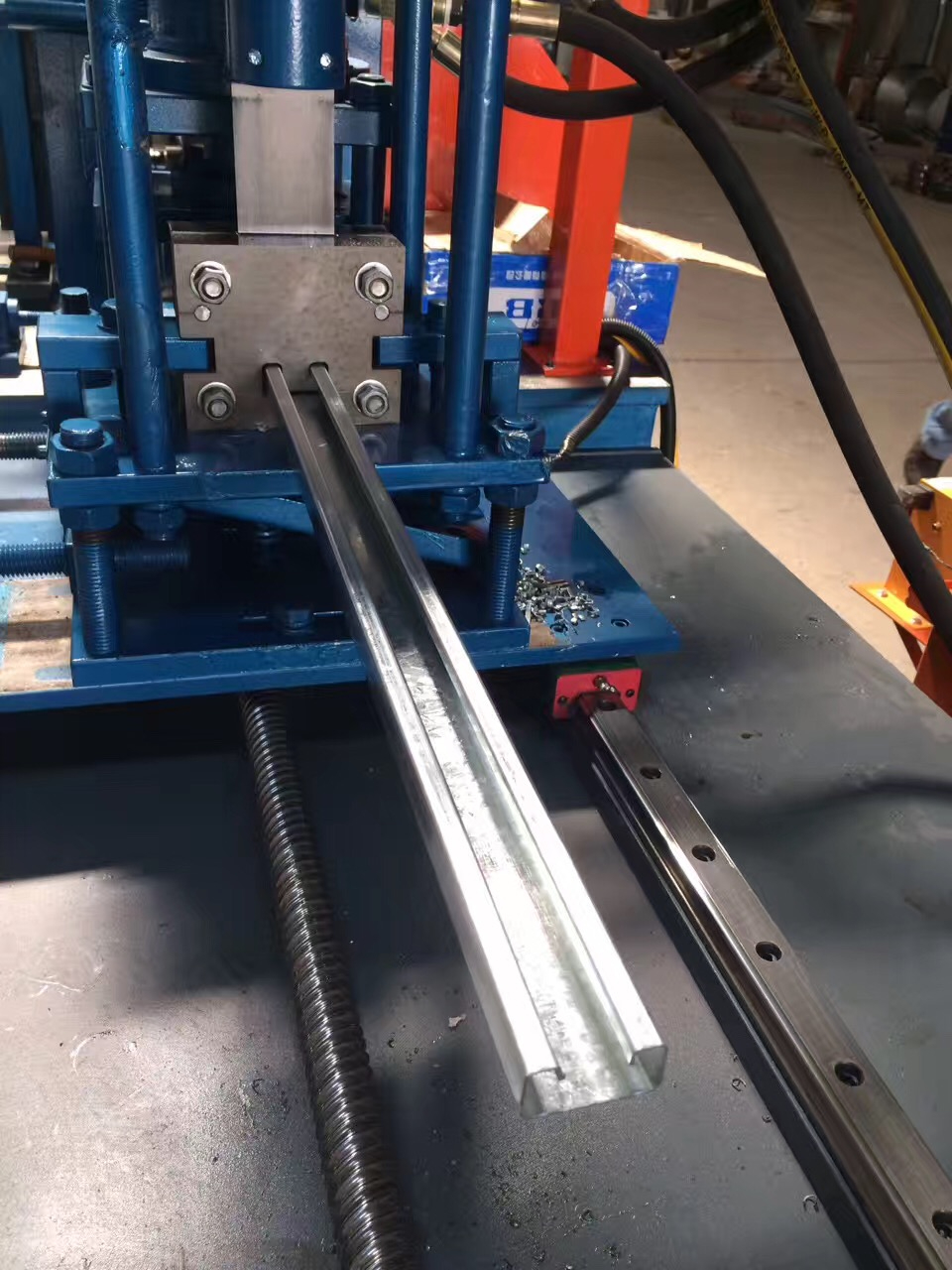

Our box beam roll forming machine is equipped with an advanced hydraulic decoiler that ensures smooth and efficient material feeding. The hydraulic decoiler handles galvanized steel coils with ease, providing a stable and reliable start to the production line. This system minimizes material waste and ensures a continuous workflow, essential for high-volume production. The machine features a sophisticated roll forming process that shapes the steel coils into precise box beam profiles. Our rollers are designed to form the material with high accuracy, producing box beams with four flat sides like a box. These box beams are crucial for creating robust and durable racking systems, widely used in warehouses, supermarkets, and other storage facilities. The precision of our forming rollers ensures that each beam meets the requirements of your specific application, providing structural integrity and longevity.

| Feature | Description |

|---|---|

| Decoiler Type | Hydraulic |

| Material | Galvanized Steel, Cold-Rolled Steel, Carbon Steel, and Stainless Steel are all suitable raw materials for our machines. |

| Coil Width is essential for determining the capacity of the purlin machine. | Customizable |

| Coil Thickness of the raw material is critical for production. | Customizable |

| Production Speed can be optimized with the right track roll forming techniques. | Adjustable |

| PLC Control | Siemens/Mitsubishi |

| Motor Power | Customizable |

Fully Automatic Operation with Customizable Profiles and Hydraulic Cutter

Our box beam roll forming machine operates fully automatically, controlled by a state-of-the-art PLC system with an intuitive HMI touch screen. The operator can easily input parameters and monitor the production process, ensuring optimal performance. This automatic operation enhances production efficiency and reduces the need for manual intervention, allowing for consistent and high-quality output. The machine is designed to produce various types of beams, including box beams, C profiles, and Zee sections. The versatility of our machine allows you to make different profiles by simply changing the rollers, adapting to various project needs. Additionally, the integrated hydraulic cutter ensures precise cutting of the formed beam to the desired length, enhancing the final product’s quality and finish. This flexibility and precision make our box beam roll forming machine a cost-effective solution for your manufacturing needs.

“Our experience with this box beam roll forming machine has been exceptional. The machine’s performance and reliability have significantly improved our production efficiency. The customer service and technical support from the team have been outstanding, making the entire process seamless and hassle-free.” – John D., Ventilation Duct Manufacturer

Robust Racking System Solutions with Comprehensive Technical Support and Warranty

Our box beam roll forming machine is ideal for producing components for various racking systems, including pallet racking, upright rack, and cantilever systems, with options for custom welds. The box beams produced by our machine are designed to be locked together, creating a strong and stable structure that can support heavy loads. This makes our machinery invaluable for manufacturers supplying the logistics and storage industry. We are committed to providing comprehensive technical support and a reliable warranty period for our customers. Our team in Wuxi, as a specialized supplier, offers on-site installation and commissioning services to ensure that your machine is set up correctly and operates smoothly from day one. We also provide detailed training for your operators, ensuring they can effectively use the machine and maintain its performance. Our support extends beyond the sale, with ongoing technical assistance and spare parts availability to keep your production line running without interruptions. We also provide you with Cable Tray Roll Forming Machine and Door Frame Roll Forming Machine services.

Environmental Impact and Sustainability

Our box beam roll forming machine is designed with environmental considerations in mind. By optimizing the roll forming process, we reduce material waste and energy consumption. The use of galvanized steel and other durable materials ensures the longevity of the final product, reducing the need for frequent replacements and further minimizing environmental impact. Our commitment to sustainability is reflected in every aspect of our machine’s design and operation. You may also be interested in our Guardrail Roll Forming Machine.

Customer Reviews

Our customers consistently praise the quality and performance of our box beam roll forming machine. Here are a few testimonials: We also provide you with Roof Panel Roll Forming Machine and Sandwich Panel Roll Forming Machine services.

- Ventilation Duct Manufacturer: “The machine has exceeded our expectations. It’s efficient, reliable, and the support from the team has been excellent. We’ve seen a significant improvement in our production output and quality.”

- Door and Gate Manufacturer: “We were impressed with the versatility of the machine. Being able to produce different profiles has allowed us to expand our product range. The hydraulic decoiler and cutter work flawlessly.”

- Ventilation Duct Engineering Contractor: “Installation and commissioning were smooth, and the training provided was very thorough. Our operators are confident in using the machine, and we’re seeing great results. Highly recommend!”

Detailed Technical Specifications

| Specification | Details |

|---|---|

| Machine Type | Box Beam Roll Forming Machine |

| Material | Galvanized Steel, Cold-Rolled Steel, Carbon Steel, Stainless Steel |

| Coil Width | Customizable |

| Coil Thickness | Customizable |

| Forming Stations | Customizable based on profile complexity |

| Production Speed | Adjustable, up to 25 m/min |

| Roller Material | High-grade alloy steel, hardened and chrome-plated |

| Main Motor Power | Customizable based on machine configuration |

| Hydraulic System Power | Customizable |

| Control System | PLC (Siemens/Mitsubishi) with HMI touch screen |

| Cutting Mechanism | Hydraulic cutter |

| Decoiler Type | Hydraulic decoiler with automatic feeding |

| Safety Features | Emergency stop buttons, safety guards |

| Dimensions | Customizable based on specific requirements |

| Weight | Customizable based on machine configuration |

Usage Instructions

- Preparation: Ensure the machine is properly installed and commissioned by our technical team. Verify all safety features are operational.

- Material Loading: Load the galvanized steel coil onto the hydraulic decoiler. Ensure the coil is securely in place and aligned correctly.

- Parameter Setting: Use the HMI touch screen to input the desired parameters, such as coil width, thickness, and desired beam length. Select the appropriate profile settings.

- Operation: Start the machine. The hydraulic decoiler will feed the coil into the roll forming stations. Monitor the process through the HMI to ensure smooth operation.

- Cutting: Once the beam reaches the desired length, the hydraulic cutter will automatically cut it.

- Collection: Collect the finished box beams from the output end. Inspect for quality and consistency.

- Maintenance: Regularly check and maintain the machine, including lubricating moving parts and inspecting the rollers and cutter for wear.

If you are also interested in the shelving industry, you can learn more about our shelf panel roll forming machine.

Conclusion

Our box beam roll forming machine is a powerful, efficient, and versatile solution for manufacturers in the ventilation duct, door and gate, and engineering contracting industries. With advanced features like the hydraulic decoiler, customizable profiles, and automatic operation, our machine enhances productivity and product quality. Our commitment to customer satisfaction, comprehensive technical support, and robust warranty ensure that you get the most out of your investment. For more information and to discuss your specific requirements, please contact us today. Let us help you revolutionize your production process with our state-of-the-art machinery.

Help Center

Have a query? Please check this question and answers

A: Roll Forming Offers Superior Speed, Consistent Quality, Minimal Waste, And Lower Labor Costs For High-Volume Standardized Profiles.

To a certain extent, yes. Modern door frame roll forming machines offer a degree of flexibility. Adjustments can be made to accommodate different profile widths and gauges. However, significant variations in profile shape usually require different sets of tooling (rollers). We can discuss your specific product range, and I can advise you on the machine configuration and tooling options that would best suit your needs, whether it’s a machine with quick-change tooling capabilities or potentially multiple machines for vastly different product lines.

After the subscription license expires, HappyAddons Pro will stop working. Without the license key, you couldn’t use the pro features and widgets of HappyAddons. So you need to renew your license before it expires. That’s the way to prevent the site breaking issue.

And don’t worry, we will send you a reminder through email and admin notice banner of your WordPress dashboard.

You will just need to have the latest version of Elementor installed on your website to be able to use the HappyAddons.

You will just need to have the latest version of Elementor installed on your website to be able to use the HappyAddons.

After the subscription license expires, HappyAddons Pro will stop working. Without the license key, you couldn’t use the pro features and widgets of HappyAddons. So you need to renew your license before it expires. That’s the way to prevent the site breaking issue.

And don’t worry, we will send you a reminder through email and admin notice banner of your WordPress dashboard.

HappyAddons is a unique collection of Addons to power up the Elementor Page Builder plugin. It works with the WordPress and Elementor Page Builder to customize your WordPress blog or Business sites.