-

nanhai,foshan, CN 526200

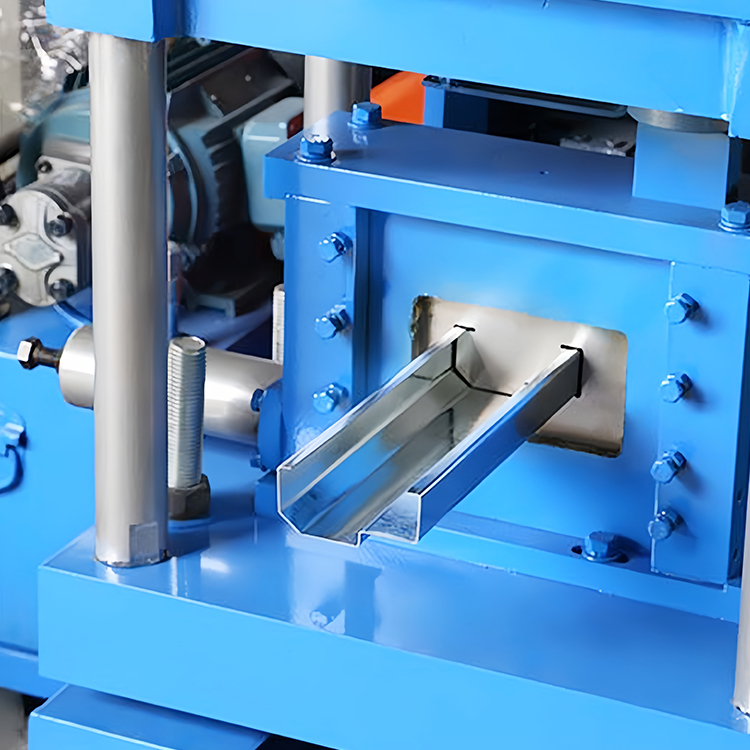

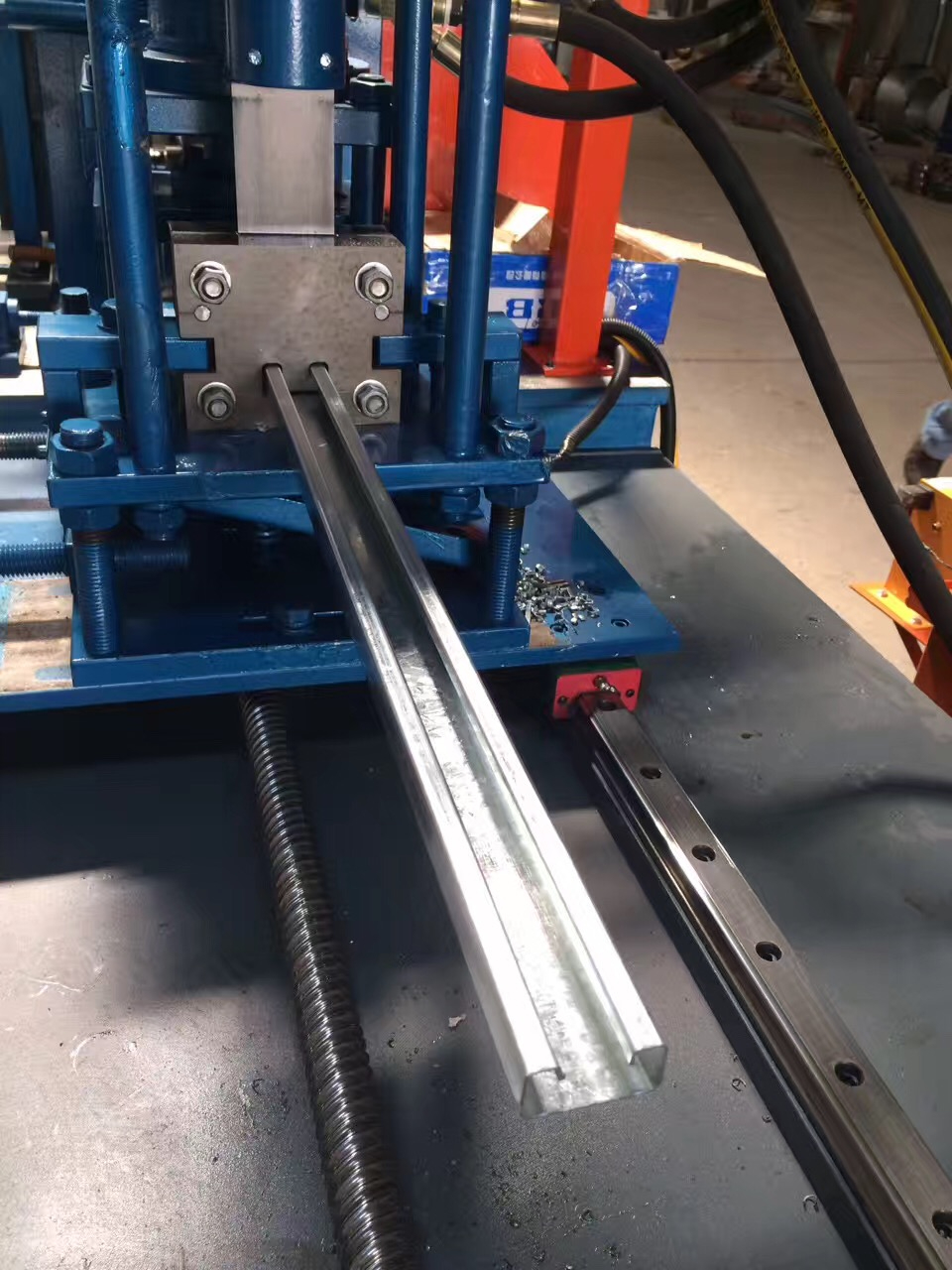

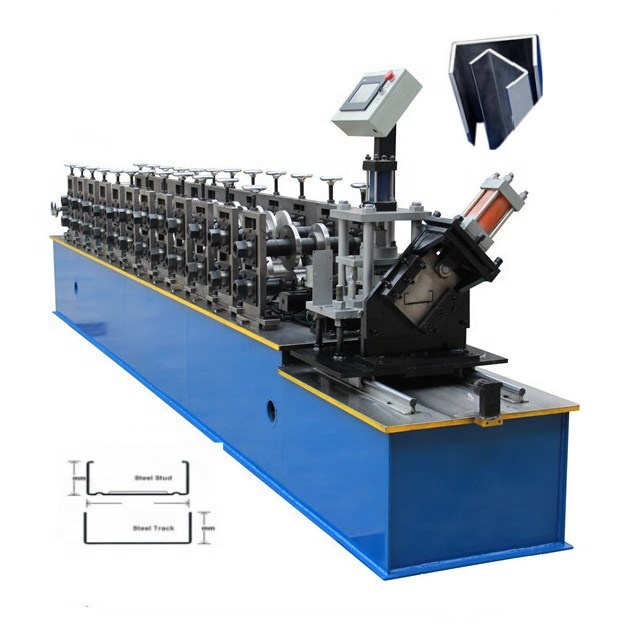

Automatic C&U Channel Steel Stud And Track Keel Roll Forming Machine

🕢 [ Fill out the form and we will respond within 30 minutes! ]

Revolutionize Your Construction Projects with Our Automatic Light Steel Keel Roll Forming Machine – The Ultimate Ceiling and Stud Solution

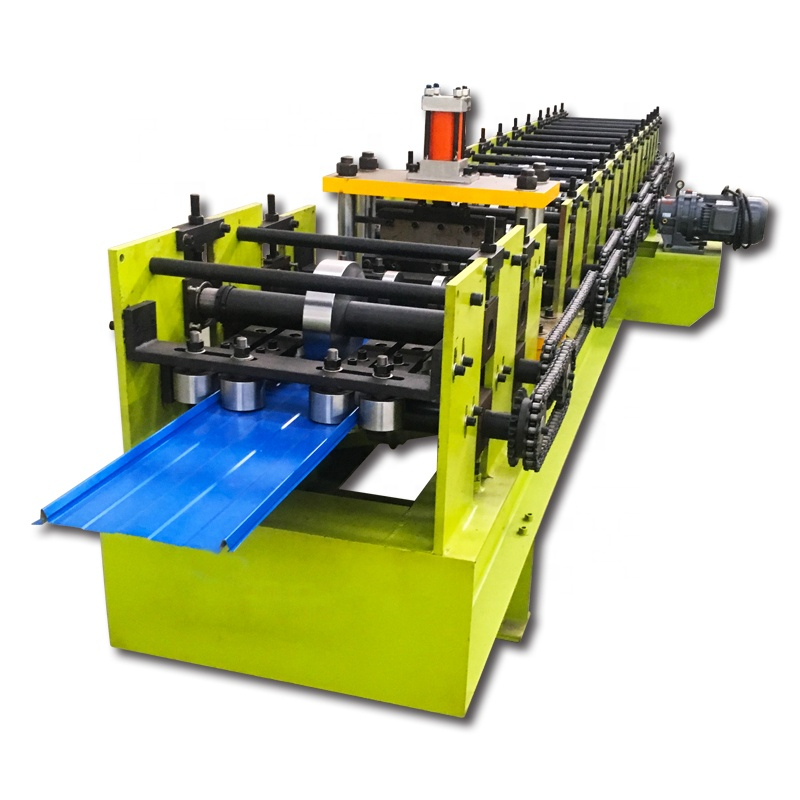

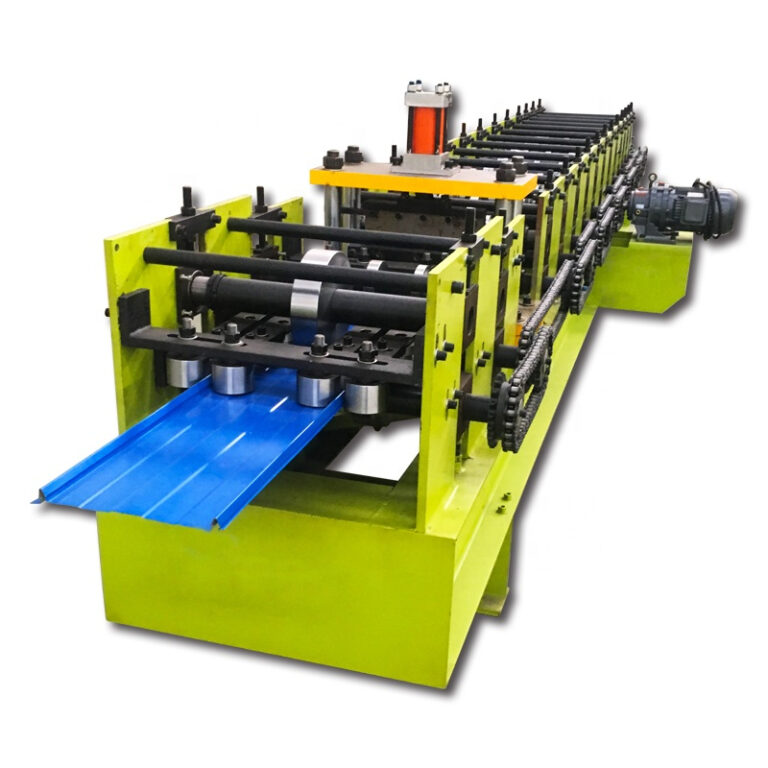

As a premier roll forming machine manufacturing plant, we are proud to introduce our state-of-the-art Automatic Light Steel Keel Roll Forming Machine. This advanced making machine is designed to meet the rigorous demands of ventilation duct manufacturers, door and gate manufacturers, and ventilation duct engineering contractors. Our light steel keel roll forming machine is engineered to produce high-quality furring channels, drywall profiles, omega shapes, and ceiling channels with unmatched precision and efficiency, ensuring there are no defects. This machine offers significant benefits, including enhanced production capacity, reduced labor costs, and superior product quality. By incorporating our light steel keel roll forming machine into your operations, you can achieve high-speed production and consistent output, ensuring that your projects are completed on time and to the highest standards. We attach great importance to quality control from the very beginning to the very end. Order from us to benefit from our commitment to excellence, comprehensive customization options, and dedicated customer support. Our machines are designed to meet your specific needs, providing reliable performance and exceptional results.

Product Description of the track roll forming machine and its features. and Key Attributes

Our light steel keel roll forming machine is a fully automatic system designed for high-speed production of various steel frame profiles. This machine is equipped with a high-precision control system, featuring a Delta PLC and servo motors, ensuring accurate and consistent production. The machinery is capable of producing light steel keels, studs, and furring channels used in drywall and ceiling applications. The production line is engineered to handle large-scale projects, providing a high degree of automation and reducing the need for manual labor. The machine’s versatility allows it to produce different sizes of steel frame profiles, making it suitable for a wide range of construction applications. The robust design and high-quality components of the roof machine ensure long-term reliability and minimal maintenance. Additionally, our roll forming machine is designed to minimize material waste, contributing to cost savings and environmental sustainability. With our machine, you can produce various types of profiles, including C U shapes and omega, providing flexibility for different project requirements. For instance, our Galvanized Punching Roll Forming Gate Door machine showcases our commitment to quality and innovation. Key Attributes:

| Attribute | Description |

|---|---|

| Automation Grade | Fully Automatic roof machine. |

| Control System | Delta PLC with Touch Screen Interface |

| Production speed is crucial for our tile production process. | Up to 60 meters per minute |

| Material | Galvanized Steel, Stainless Steel |

| Profile Types | C U, Omega, Furring Channel, Ceiling Steel, Stud |

| Thickness Range | 0.3 – 1.2 mm |

| Warranty for the machine product on alibaba.com. | 12 Months, with extended options available for the machine product on alibaba.com. |

| Customization | Available based on customer’s specific requirements |

| Motor Power | Customizable, typically 7.5 kW – 15 kW |

| Voltage | 380V/415V/440V, 50/60 Hz (Customizable) |

| Drive Type | Servo Motor |

| Machine Weight | Approximately 5 – 8 tons, depending on configuration |

| Dimensions | Customizable track roll forming based on production line layout. |

| Safety Features | Emergency stop buttons, safety guards, and overload protection are essential safety features for the roof machine. |

| Additional Features | Automatic lubrication system, remote diagnostics, energy-saving mode |

| Certifications | ISO 9001, CE certified for our roof machine. |

| After-Sales Service for our gutter and roof machines is readily available. | On-site installation, commissioning, training, and ongoing technical support |

| Packaging | Standard export packaging with protective film and wooden case |

| Lead Time | 30-45 days, depending on customization and order volume for the roof machine. |

| Payment Terms | T/T, L/C |

| Shipping | By sea, with options for expedited shipping available |

Customization and Lead Time

We understand that each customer has unique requirements. Therefore, our light steel keel roll forming machine offers extensive customization options. From specific profile designs to production speed adjustments, we work closely with our clients to tailor the machinery to their exact needs. Our engineers are dedicated to providing solutions that enhance your operational efficiency and product quality. Our standard lead time is approximately 30-45 days, depending on the complexity of the customization and the current order volume. We strive to deliver your machine promptly, ensuring it meets all your specifications. During the production process, we maintain open communication, providing regular updates on the progress. Our commitment to timely delivery and customer satisfaction sets us apart as a trusted supplier in the industry. We attach great importance to quality.

“The customization options provided by this manufacturer are exceptional. They worked with us to develop a machine that perfectly fits our production needs. The lead time was reasonable, and the machine’s performance has exceeded our expectations.” – Sarah K., Door and Gate Manufacturer

Our Windows Door Frame Gat Rolling Forming Machine also offers similar customization benefits.

Basic Info and Related Searches

Our company, as a leading technology co. ltd, specializes in the manufacture of high-quality roll forming machinery. Our products are widely used in various countries and regions, and we are committed to providing users with best-selling, cost-effective processing equipment. Our light steel keel roll forming machine is a testament to our dedication to innovation and quality. In addition, we also provide Metal Siding Roll Forming Machine and Fully Automatic Box Beam Roll Forming Machine.

Related Searches:

- High-speed roll forming machine

- Steel frame production line

- Drywall profile making machine

- Ceiling channel roll forming machine

- Omega profile roll forming machine

- Light gauge steel framing machine

- Roll forming machine metal stud

- Automatic C U channel roll forming machine

- Steel roll forming machinery

Basic Info:

| Category | Details |

|---|---|

| Product Name | Light Steel Keel Roll Forming Machine |

| Application | Light Steel Keel,Stud, Furring Channel, Drywall, Ceiling Steel |

| Automation | Fully Automatic |

| Material | Galvanized Steel, Stainless Steel |

| Warranty | 12 Months |

| Certification | ISO 9001, CE |

| Supplier | Leading Technology Co., Ltd |

| Export Markets | Global, with a focus on North America, Europe, and Southeast Asia |

| Service | Comprehensive after-sales support, including installation and training |

Environmental Impact

Our roll forming machines are designed with environmental considerations in mind. By optimizing the production process, we reduce material waste and energy consumption. The use of durable materials like galvanized steel ensures the longevity of the final product, minimizing the need for frequent replacements and thus reducing the environmental footprint.

Customer Reviews

Our customers consistently praise the quality and performance of our light steel keel roll forming machine. Here are a few testimonials:

- Ventilation Duct Manufacturer: “This machine has revolutionized our production process. The speed and accuracy are incredible, and the ability to produce different profiles has given us a competitive edge. The support from the team has been outstanding.”

- Door and Gate Manufacturer: “We were looking for a reliable machine to enhance our production capacity, and this roll forming machine has delivered beyond our expectations. The customization options allowed us to tailor it to our specific needs, and the results have been fantastic.”

- Ventilation Duct Engineering Contractor: “The machine’s performance is excellent, and the PLC control system makes it easy to operate. The warranty and after-sales service provide peace of mind, knowing that we have support whenever needed. Highly recommend this machine to anyone in the industry.”

Our Automatic C\&U Channel Steel Stud And Track Keel Roll Forming Machine has also garnered positive reviews for its reliability and efficiency.

Usage Instructions

- Preparation: Ensure the machine is properly installed and commissioned by our technical team. Verify all safety features are operational.

- Material Loading: Load the galvanized steel coil onto the decoiler. Ensure the roof machine coil is securely in place and aligned correctly.

- Parameter Setting: Use the HMI touch screen to input the desired parameters, such as coil width, thickness, and desired profile type.

- Operation: Start the machine. The control system will manage the feeding, forming, and cutting processes automatically. Monitor the operation through the HMI.

- Collection: Collect the finished steel profiles from the output end. Inspect for quality and consistency.

- Maintenance: Regularly check and maintain the machine, including lubricating moving parts and inspecting the rollers for wear.

Conclusion

Our Automatic Light Steel Keel Roll Forming Machine is an essential tool for any construction professional looking to enhance their production capabilities. With its high-speed operation, precise engineering, and extensive customization options, this roof machine offers unparalleled performance and value. Our commitment to quality, timely delivery, and customer satisfaction makes us the ideal partner for your manufacturing needs. Contact us today to learn more about how our light steel keel roll forming machine can transform your operations and help you achieve your production goals.

Help Center

Have a query? Please check this question and answers

A: Roll Forming Offers Superior Speed, Consistent Quality, Minimal Waste, And Lower Labor Costs For High-Volume Standardized Profiles.

To a certain extent, yes. Modern door frame roll forming machines offer a degree of flexibility. Adjustments can be made to accommodate different profile widths and gauges. However, significant variations in profile shape usually require different sets of tooling (rollers). We can discuss your specific product range, and I can advise you on the machine configuration and tooling options that would best suit your needs, whether it’s a machine with quick-change tooling capabilities or potentially multiple machines for vastly different product lines.

After the subscription license expires, HappyAddons Pro will stop working. Without the license key, you couldn’t use the pro features and widgets of HappyAddons. So you need to renew your license before it expires. That’s the way to prevent the site breaking issue.

And don’t worry, we will send you a reminder through email and admin notice banner of your WordPress dashboard.

You will just need to have the latest version of Elementor installed on your website to be able to use the HappyAddons.

You will just need to have the latest version of Elementor installed on your website to be able to use the HappyAddons.

After the subscription license expires, HappyAddons Pro will stop working. Without the license key, you couldn’t use the pro features and widgets of HappyAddons. So you need to renew your license before it expires. That’s the way to prevent the site breaking issue.

And don’t worry, we will send you a reminder through email and admin notice banner of your WordPress dashboard.

HappyAddons is a unique collection of Addons to power up the Elementor Page Builder plugin. It works with the WordPress and Elementor Page Builder to customize your WordPress blog or Business sites.