-

nanhai,foshan, CN 526200

Revolutionize Your Production with Advanced Roll Forming Machines

As a premier manufacturer of roll forming machines, we understand the critical role that efficient and precise machinery plays in the success of ventilation duct manufacturers, door and gate manufacturers, and ventilation duct engineering contractors. Our rollforming solutions are designed to optimize your production processes, providing you with high-quality metal roll products that meet the stringent demands of your industries. This article will explore the intricacies of roll forming, highlighting the benefits of our machines and the reasons why partnering with us is the best decision for your business. For those interested in exploring more about our company, feel free to jump to content further down.

Our roll forming machines are engineered to deliver exceptional performance, enhancing your production capabilities while reducing operational costs. By utilizing our state-of-the-art machinery, you gain a competitive advantage through superior product quality, faster production times, and reduced labor costs. We are committed to providing comprehensive solutions that encompass training, maintenance, and dedicated after-sales support, ensuring that you receive the best value and expertise in the industry.

Table of Contents

Understanding the Intricacies of Roll Forming Processes

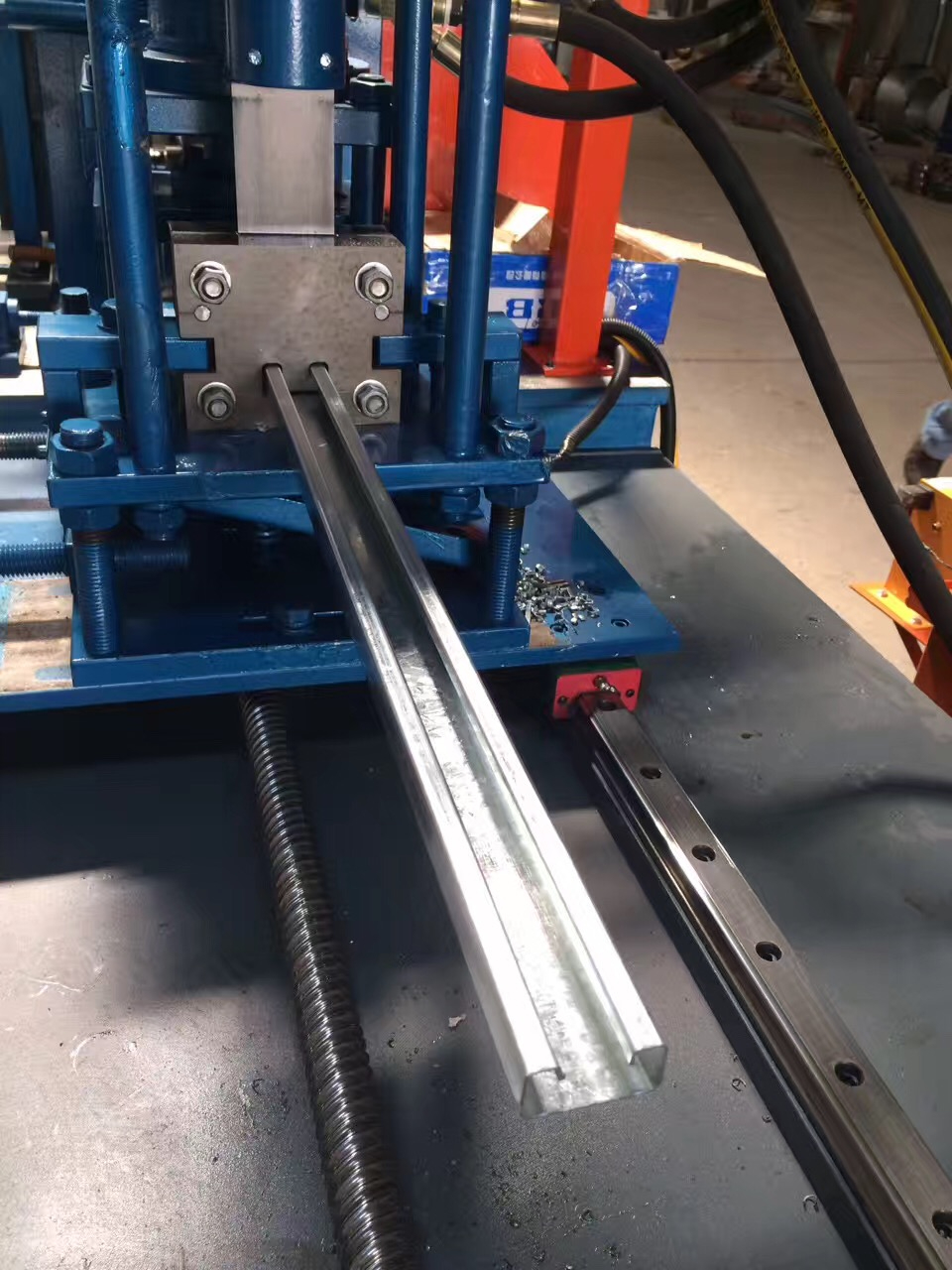

The roll forming process is a highly efficient method for shaping sheet metal into a wide range of profiles. Unlike other forming processes, roll forming involves bending the metal strip incrementally as it passes through a series of rollers. Each set of rollers performs a small part of the bend, gradually shaping the metal until it achieves the desired shape. This method is particularly effective for producing parts with consistent cross-sections and long lengths. One significant advantage of roll forming is its ability to handle large quantities of material, making it ideal for mass production.

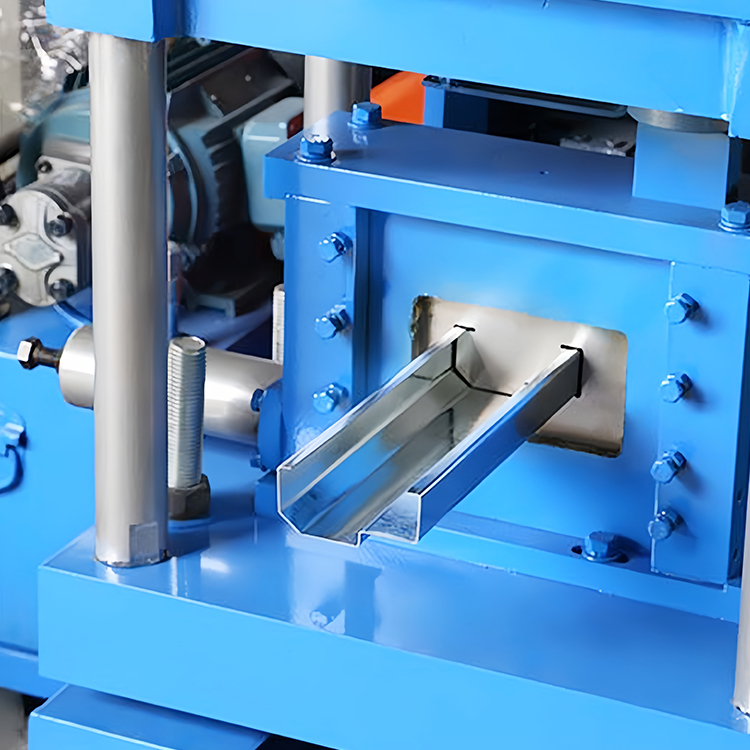

Our machines are designed to manage various types of metal coils, including galvanized steel, carbon steel, and aluminum. The process begins with a large coil of sheet metal that is fed through an uncoiler and then through a flattener to remove any coil set. Next, the metal is fed into the roll forming line, where it goes through multiple forming stations. Each station consists of pairs of roller die stands that progressively bend the metal. At the end of the roll forming line, the finished product is cut to length using a precise cutting mechanism. This ensures that each metal part is produced to the specified length with high accuracy. For specialized components, our Automatic C&U Channel Steel Stud And Track Keel Roll Forming Machine is an excellent option.

Advanced Features of Our Rollforming Machines

Our rollforming machines are equipped with a range of advanced features designed to enhance productivity and product quality. These machines are capable of producing complex profiles with tight tolerance, making them suitable for a wide array of applications, including metal roofing, door frames, and ventilation ducts.

The roll forming line is engineered for continuous operation, allowing for high-speed production with minimal downtime. Our machines can achieve production speeds of up to several feet per minute, depending on the type of roll and the complexity of the profile being formed. The use of high-quality rollers ensures that each bend is precise and consistent, resulting in a finished product that meets the highest quality standards. Our roll formers are also equipped with advanced punch mechanisms, allowing for the creation of holes and other features as needed. This capability eliminates the need for secondary operations, further streamlining the production process. Additionally, our metal siding roll forming machine is designed to produce high-quality siding panels efficiently.

| Feature | Description | Benefit |

|---|---|---|

| Rollers | High-grade steel rollers designed for longevity and precision. | Consistent profile shaping and reduced wear and tear. |

| Punch Unit | High-precision punching for accurate hole placement. | Perfect alignment for fittings and fixtures, eliminating the need for secondary operations. |

| Uncoiler | Heavy-duty uncoiler to handle large metal coils. | Continuous material feed, reducing downtime and increasing productivity. |

| Cutting System | Integrated cutting mechanism for precise cut to length. | Accurate cuts, minimizing material waste and ensuring clean edges. |

| Control System | User-friendly control panel for easy operation and monitoring. | Streamlined production process, easy adjustments, and real-time performance data. |

| Roll Forming Line | Multiple forming stations for gradual metal shaping. | High-speed production with minimal downtime, producing complex profiles with tight tolerance. |

| Speed | Production speeds up to several feet per minute, depending on type of roll and profile. | Rapid production, meeting high-volume demands efficiently. |

| Materials | Capable of handling various metal coils, including galvanized steel and carbon steel. | Versatile production capabilities, suitable for diverse applications like metal roofing and more. |

Versatility and Applications of Roll Forming

Roll forming is a versatile process that can be used to create a wide range of products. Our machines are designed to handle various types of sheet metal, making them suitable for diverse applications across different industries. This versatility is one of the key reasons why roll forming is ideal for producing components for ventilation systems, doors, gates, and other structural elements.

One of the primary applications of our rollforming machines is in the production of metal roofing panels. The ability to produce long, continuous panels with consistent profiles makes roll forming an ideal choice for this application. Additionally, our machines can be used to create components for doors and gates, including frames, panels, and other structural elements. The precision and consistency offered by roll forming ensure that these components meet the highest standards of quality and durability. For instance, our fully automatic box beam roll forming machine is perfect for creating robust structural components.

Roll forming is also widely used in the manufacturing of ventilation ducts. The ability to create complex profiles with tight tolerances makes it an ideal process for producing ductwork that meets the specific requirements of HVAC systems. Our machines are capable of producing a variety of duct profiles, ensuring that manufacturers can meet the diverse needs of their customers. The high-speed production capabilities of our machines further enhance their suitability for this application, allowing manufacturers to meet tight deadlines and maintain efficient production schedules. Check out our galvanized punching roll forming gate door machine for specialized door and gate components.

Environmental Impact

We are committed to sustainable manufacturing practices. Our roll forming machines are designed to minimize waste and energy consumption. The precision of the roll forming process ensures that material usage is optimized, reducing scrap and waste. Furthermore, the energy-efficient design of our machines helps lower your operational costs and reduces your environmental footprint. By choosing our products, you are investing in machinery that aligns with environmentally responsible practices.

Customer Reviews

Our commitment to quality and customer satisfaction is reflected in the positive feedback we receive from our clients. Here are a few testimonials:

- “The roll forming machine has exceeded our expectations. The precision and speed are unmatched, and the support from the team has been outstanding.” – Ventilation Duct Manufacturer

- “We were able to double our production of metal roofing panels with this machine. It’s a game-changer for our business.” – Door and Gate Manufacturer

- “The versatility of the rollforming machine has allowed us to expand our product line and meet the diverse needs of our customers.” – Ventilation Duct Engineering Contractor

- https://www.youtube.com/embed/_05iRC_ee90

Usage Instructions

Our roll forming machines are designed for ease of use. The user-friendly interface and intuitive controls make operation straightforward. We provide comprehensive training to ensure that your team can operate the machinery efficiently and safely. Additionally, our detailed user manuals and instructional videos offer step-by-step guidance on setup, operation, and maintenance.

- Setup: Ensure the machine is properly installed and aligned. Load the metal coil onto the uncoiler.

- Operation: Input the desired specifications into the control panel. Start the machine and monitor the roll forming process.

- Maintenance: Regularly inspect and maintain the rollers, punch units, and other components to ensure optimal performance.

Technical Specifications

| Specification | Details |

|---|---|

| Machine Type | Roll Forming Machine |

| Material | Sheet Metal, Galvanized Steel, Carbon Steel, Aluminum |

| Thickness | Depending on the type of roll and material |

| Forming Speed | Up to several feet per minute |

| Roller Stations | Multiple stations for gradual shaping |

| Punch Capacity | High-precision punch units for accurate hole placement |

| Control System | User-friendly control panel with advanced monitoring features |

| Uncoiler | Heavy-duty uncoiler for handling large metal coils |

| Cutting Mechanism | Integrated system for precise cut to length |

| Dimensions | Customizable based on specific production requirements |

| Weight | Varies depending on machine configuration |

| Power Supply | Standard industrial power supply |

| Safety Features | Emergency stop buttons, safety guards |

| Warranty | Comprehensive warranty covering parts and labor |

| Certification | Compliant with industry standards and certifications |

| Additional Features | Roll forming line integration, custom profile design, portable rollforming machinery options |

| Customization | Available upon request to meet specific production needs |

| Support | Comprehensive training, maintenance, and after-sales support provided by our expert team |

Our roll forming machines are built to last, with robust construction and high-quality components. The machines are designed for continuous operation, capable of producing a wide range of profiles at high speeds. The advanced control system allows for precise adjustments and monitoring, ensuring that each product meets the highest quality standards. These machines also excel in producing specialized components, making them a versatile addition to any production line. For more details, feel free to contact us.

Why Choose Us?

Choosing the right machine manufacturer is crucial for the success of your business. Here are some reasons why you should partner with us:

- Expertise: With years of experience in the industry, we have the knowledge and expertise to provide the best roll forming solutions.

- Innovation: We are constantly innovating and improving our machinery to meet the evolving needs of the market.

- Quality: Our machines are built to the highest standards, ensuring reliability and longevity.

- Support: We offer comprehensive support, from installation and training to maintenance and after-sales service.

Partnering with us means investing in a long-term relationship focused on your success. Our team is dedicated to providing the best possible solutions and support to help you achieve your production goals. For more specialized needs, our windows door frame gat rolling forming machine offers additional features for enhanced productivity.

By choosing our roll forming machines, you are not just purchasing a product; you are gaining a partner dedicated to your success. Contact us today to learn more about how our rollforming solutions can transform your production capabilities.